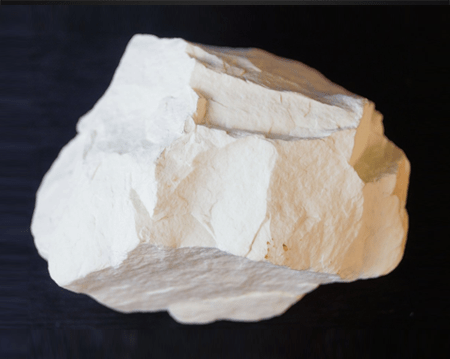

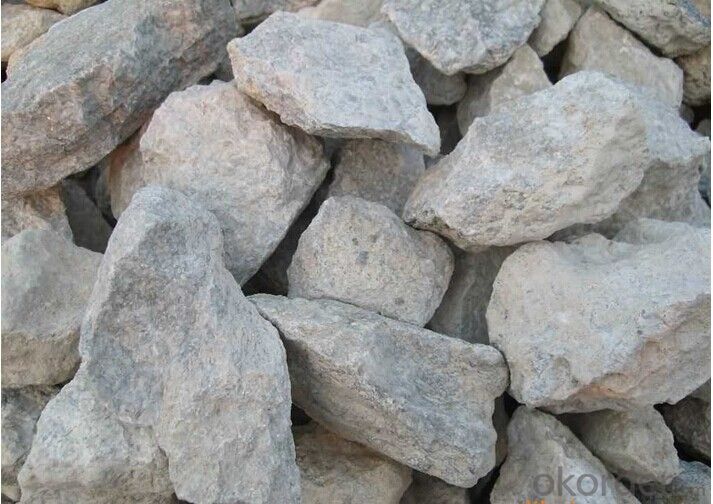

Raw Magnesite

Cryptocrystalline Magnesite MgCO3 with extremely low silica and iron content, white colour, and very low level of heavy metals.

RMA is a raw magnesite milled product with 90% MgO content on ignited basis, which is used in the production of ceramics (tiles etc.).

Available sizes at d90<75μm or d90<45μm